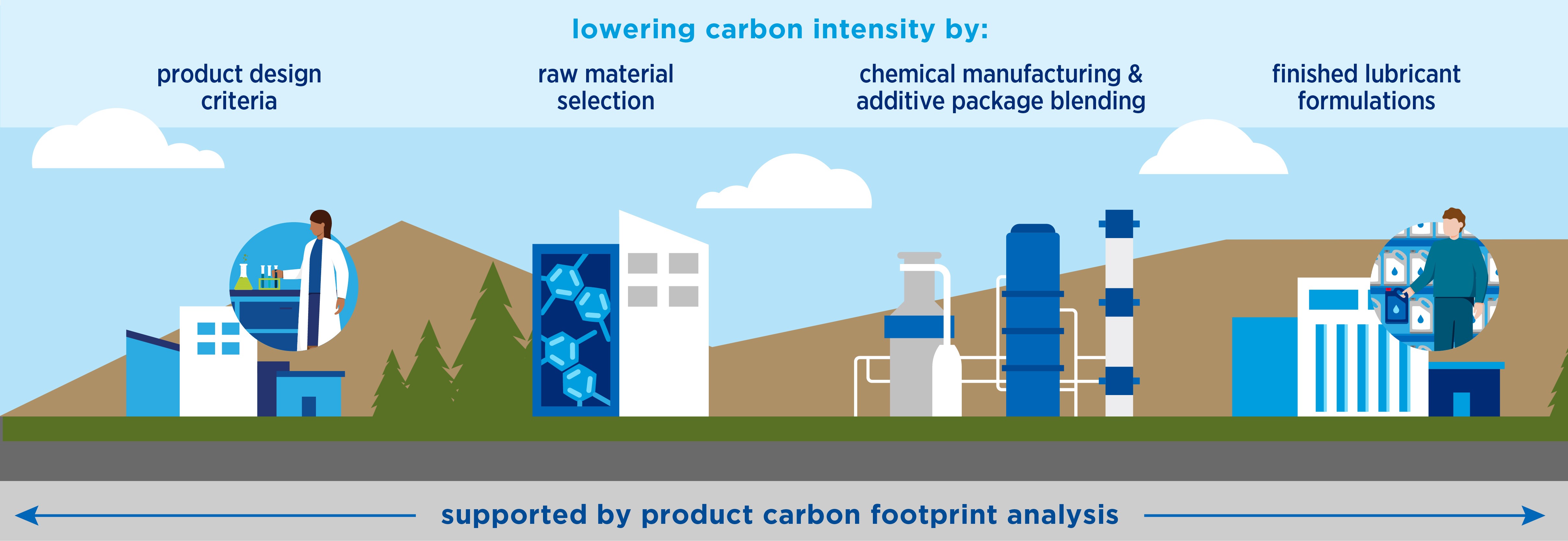

lower carbon intensity focus areas

A lifecycle approach to carbon accounting facilitates informed decision making throughout the value chain. This accounting approach can be used to quantify the carbon intensity associated with a good or service, inclusive of some direct and indirect emissions. Such an approach could enable policymakers to drive the most pragmatic policy, incentivize producers to abate more, inform buyers on making lower carbon choices in a standardized manner and identify more cost-efficient emissions reduction options.

As part of our lower carbon journey at Chevron Oronite, we have developed a cradle-to-gate Product Carbon Footprint (PCF) calculation methodology to evaluate the carbon intensity of our products. This model includes relevant greenhouse gas emissions associated with product production, covering raw material procurement, and the manufacturing of our additive chemicals and formulated products. Additional contributions from waste transportation and treatment, intercompany transfers, upstream fuels and electricity production, and off-site storage have also been included. The system boundary specifically excludes packaging, outbound transportation, and any use or end of life stages. Our methodology has been reviewed by TUV Rheinland for compliance with ISO 14067:2018 standards and Together for Sustainability guidelines.

Here are a few things we’re working on to lower the carbon intensity of our products.

product design criteria

As future additive chemistries and technology formulations are developed, the product carbon footprint is now evaluated as part of our standard design criteria. We look for innovative, lower carbon intensity materials, and new processing technologies for the next generation of high-performance lubricants while simultaneously lowering the product carbon intensity.

raw material selection

Chevron Oronite is collaborating with many of our suppliers to obtain high quality primary carbon footprint data for our purchased materials. We are also working closely with our suppliers to help identify and foster product carbon footprint reduction opportunities, including the use of renewable, recycled, and other lower carbon intensity materials.

chemical manufacturing and additive package blending

Chevron Oronite utilizes the same robust Chevron marginal abatement cost curve (MACC) process for identifying reduction opportunities across our facilities. This includes investing in new processing equipment with higher efficiency, incorporating renewable energy from sources such as solar, wind, and hydroelectric, upgrading our steam systems, improving waste management, and modernizing our operations. To date, more than half of our facilities use renewable electricity and we are looking for ways to expand this even more.

finished lubricant formulations

We collaborate with our customers to help enable lower carbon intensity finished lubricants. This includes delivering innovative additive technology designed to be used with lower carbon intensity base oils and lowering the treat rates of our additive packages.

our lower carbon stories